Custom Precision Spare Parts CNC Machinery Shop With High Service And Quality

- Application: Contact Yize Mould Donggu...

- Market Type:After Market

- FOB Price: USD 0.8666

- Other Price Term: Exw

- Payment Terms: L/C, T/T

- Samples: Free

- Minimum Order: 1PCS

Quick Details

-

Material:

Steel

-

Material Quality:

ISO900

- Samples:

Free

- Delivery Time:

7-15 Days After T/T 30% Deposit

- Packing:

1.Coating Oiling To Form A Protective Coating Against Rust, Corrosion, Etc 2.Packed With Pearl Cotton To Shake Proof 3.Packed In A Plastic Box Or PE B

- Delivery Port:

Shenzhen

- Max. Production Capacity:

10000 Piece/Pieces Per Day

- Export Ratio:

91% - 100%

- OE Experience:

No

Product Name:Custom Precision Spare Parts CNC Machinery Shop With High Service And Quality

Custom Precision Spare Parts CNC Machinery Shop With High Service And Quality

Application

Contact Yize Mould Dongguan YIZE MOULD Co., LTD carbide punching pins Address: No.62, Jinghai East Road, Shatou District, Changan Town, Dongguan City, Guangdong Province, China TEL:+86-769-81888522 Email:dgyize@dgyize.com More information about carbide punching pins of YIZE,please visit our official website:

Product Description:

Custom Precision Spare Parts CNC Machinery Shop With High Service And Quality

sisazhietyize

| Die Tipe | Mobile phone mould parts |

| Draw Format | Auto CAD/DWG/PDF ect |

| Tolerance | ±0.002mm |

| Hardness | Upon request |

| Mould size | Customized size |

| Production Application | Mobile/ laptop/ digital cameral/ HD digital TV/ automobile/ electron ect |

| Certificate | ISO 9001:2008 & ISO 14001:2004 |

| Surface Tratement | Polishing/ mirror polishing/ plating/ heat treatment or according to your parts |

| Precision Machining | CNC/ surface granding machine/ WEDM-HS/ sandik wire cutting/ EDM/ WIDA optical curve grinder ect |

| Measuring Instruments | Profile projector/ electronic height gauge/ CMM/ 2D measuring instrument/ vernier caliper/ microscope/ micrometer ect |

| Steel Material | KD20/ SKD11/ CD650/ 12EF/ YG15/ ASP23/ ASP60/ SKH-9/ Cemented Carbide ect |

| Mould Life | Depends on the steel material and your request |

| Main Service | Made-to-order |

About Dongguan YIZE

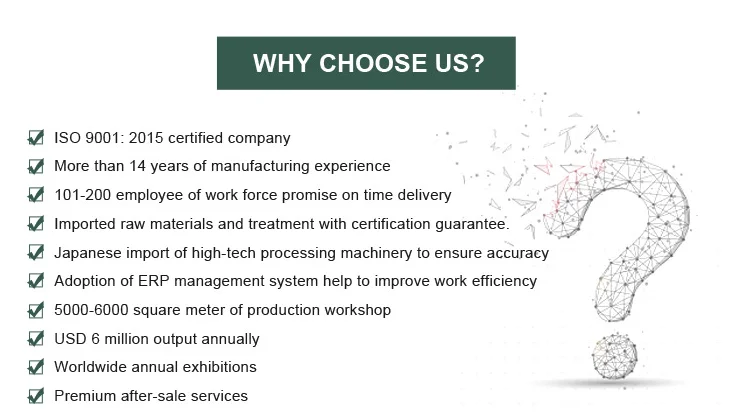

1.With 15-year exploration, each step of process in YIZE is checked by senior technicians with over ten-year experience to ensure 100% quality from all process.

2.YIZE mould has good service system and short delivery time, which only needs 7 to 10 production days from order to delivery, letting customers enjoy high-qualified service.

mold spare parts

Dongguan yize's main products: PG parts processing, plastic mold parts processing. Complete supporting production line, with "excellent quality, reasonable price, fast delivery, comprehensive service" adhere to the business philosophy of "integrity, innovation, professionalism, and excellence", and gradually improve the management system.Comprehensive quality assurance, to provide customers with "reliable, high-quality" products, we cherish and thank all walks of life for giving us the opportunity to serve, welcome all walks of life to inquire and guide, and are willing to develop hand in hand with friends at home and abroad.

-Are you worried about these issues-

-

Product ideas cannot be realized. - Cannot meet the needs of new users, poor after-sales service and poor product quality.

- The production cycle is long.

- No suitable manufacturer's processing plant can be found.

- The production process is poor, and the delivery time is not guaranteed.

Peoples who is looking for precision tungsten steel round punch supplier can give YIZE MOULD a chance,and we believe that you will never regret choosing us in the future!

According to the modelsView More

Supplier Details

You May Like:

-

Mold Die Punch And Die Tooling High Quality Tungst ...

Application: Dongguan YIZE MO ...

-

Bushing Wall Plug Socket Power Socket Plastic Inje ...

Application: Dongguan YIZE MO ...

-

Punching Mold Shaping Mode Precision Punch And Die

Application: Dongguan YIZE MO ...

-

solid tyre mould

Application: all kind of soli ...

OEM No: 8480790 ...

-

Magnetic Roof Hat (Magnetic Roof Top Magnetic Roof ...

Application: toyota

-

100% Genuine Zotye Spare Parts Wheel Opening Mould ...

Application: Zotye

OEM No: 66850-D ...

-

HYUNDAI ATOS FOG LAMP COVER 86611-06020

Application: USED FOR HYUNDAI ...

OEM No: 86611-0 ...

-

RENAULT Truck EBS Modulator 5010457556

Application: RENAULT PREMIUM ...

OEM No: 5010457 ...

-

Plastic Over Molding Part

Application: Universal

Related Product Tags:

air conditioner mold , air conditioner mould , amplifier module , bearing mould , blower control module , bumper mold , automobile bumper mold , auto bumper mold , auto bumper mould , rear bumper mould , plastic bumper mould , automobile bumper mould , bumper mould , car bumper mould , front bumper mould , car bumper mold , casting mould , electronic control module Didn't find what you are looking for?

Please send us Your Search Requirement, or you can Post a Buying Lead,

suppliers may contact you actively.

Please send us Your Search Requirement, or you can Post a Buying Lead,

suppliers may contact you actively.