Hot Selling Product Mould For Tungsten Carbide Powder Pressing Mold Metallurgy Die

- Application: Dongguan YIZE MOULD Co.,L...

- Market Type:After Market

- FOB Price: USD 1.599

- Other Price Term: Exw

- Payment Terms: L/C, T/T

- Samples: Free

- Minimum Order: 1PCS

Quick Details

-

Material:

Steel

- Samples:

Free

- Delivery Time:

7-15 Days After T/T 30% Deposit

- Packing:

1.Coating Oiling To Form A Protective Coating Against Rust, Corrosion, Etc 2.Packed With Pearl Cotton To Shake Proof 3.Packed In A Plastic Box Or PE B

- Delivery Port:

Shenzhen

- Max. Production Capacity:

10000 Piece/Pieces Per Day

- Export Ratio:

91% - 100%

- OE Experience:

No

Product Name:Hot Selling Product Mould For Tungsten Carbide Powder Pressing Mold Metallurgy Die

Hot Selling Product Mould For Tungsten Carbide Powder Pressing Mold Metallurgy Die

Application

Dongguan YIZE MOULD Co.,LTD Address: 3/F, Factory Building, No.62, Jinghai East Road, Shatou District, Changan Town, Dongguan City, Guangdong Province, China TEL:+86-769-81888522 Email:alisa.chen@dgyize.com More information about the precision stamping mold parts of YIZE,please visit our official website:

Product Description:

Hot Selling Product Mould For Tungsten Carbide Powder Pressing Mold Metallurgy Die

sisazhietyize| Design Software | UG, ProE, Auto CAD, Solidworks, etc. |

| Precision(mm) | 0.002 |

| Hardness HRA | HRA58-62 |

| Service Life | 100000 to 300000 times |

| Equipments |

High speed CNC, standard CNC, EDM, Wire cutting, Grinder, Lathe, Milling machine, plastic injection machine |

| Surface Finish | Plating, Polishing, Heat treatment |

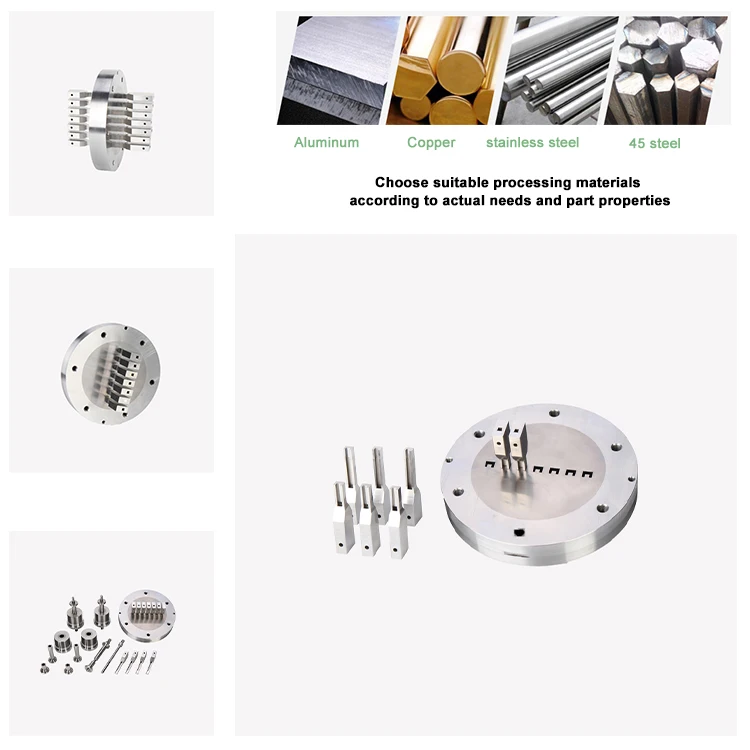

| Material | Stainless Steel, Brass, Copper, Aluminum, Steel, Carbon Steel etc. |

| Service | OEM &ODM service |

| Size | Customized |

Dongguan Yize Mould Co., Ltd. is a professional manufacturer of precision round parts. In order to produce more precise precision round parts, we gradually use CNC machine tools to replace ordinary machine tools, so as to deliver high-quality and high-precision precision round parts. Customer hands.

1. The precision of flat grinding can reach 0.001mm, and the grinding angle can reach r0.015. The cumulative tolerance of 100 pieces can be controlled within 0.01mm.

2. The thinnest copper wire used for wire cutting is up to 0.1mm, and the wire cutting accuracy is up to 0.005mm. The parallelism, perpendicularity and straightness can reach 0.002mm.

3.The discharge precision can reach 0.005mm, the discharge angle can reach r0.015, and the discharge finish can reach Ra0.2.Dongguan Yize mould is a high quality connector mould parts manufacturerwhere you can buy mould parts with good quality.

Supplier Details

You May Like:

-

Precision Powder Metallurgy Tungsten Carbide Die M ...

Application: Dongguan YIZE MO ...

-

Factory Price Of Metal Metallurgy Machinery Parts ...

Application: Dongguan YIZE MO ...

-

Manufacturer High Precision CNC Machining Powder M ...

Application: Dongguan YIZE MO ...

-

Test0524

Application: BAIC BJEV, Chevr ...

-

Power Take Off. N 1701513-01

Application: Foton

OEM No: N 17015 ...

-

Engine Mounting For TOYOTA 12302-13042

Application: TOYOTA

OEM No: 12302-1 ...

-

Planetary Gear/ Gear Ring for FAW, Dongfeng

Application: FAW, Dongfeng

-

High Quality Piston Bush

Application: Audi/ A6l(china) ...

-

After the Motor Cover

Application: General

Related Product Tags:

coil wire , magnetic ring , oil pump rotor , oil pump rotors , oil pump rotor gear , pump rotor , oilpump rotor , rod guide , Sinter Rod Guide , Powder Metallurgy Rod Guide , Metallurgy Rod Guide , Absorber Rod Guide , sintered part , sintered partsPlease send us Your Search Requirement, or you can Post a Buying Lead,

suppliers may contact you actively.