Global Auto Parts & Accessories Marketplace

Custom Injection Molding Plastic Parts Mould Accessories

- Application: Contact Yize Mould Donggu...

- Market Type:After Market

- FOB Price: USD 1.999

- Other Price Term: Exw

- Payment Terms: L/C, T/T

- Samples: Free

- Minimum Order: 1PCS

Quick Details

-

Material:

Aluminum

-

Technics:

Broaching

- Samples:

Free

- Delivery Time:

7-15 Days After T/T 30% Deposit

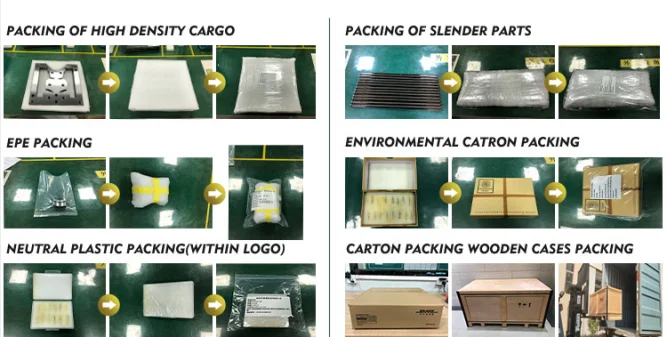

- Packing:

1.Coating Oiling To Form A Protective Coating Against Rust, Corrosion, Etc 2.Packed With Pearl Cotton To Shake Proof 3.Packed In A Plastic Box Or PE B

- Delivery Port:

Shenzhen

- Max. Production Capacity:

10000 Piece/Pieces Per Day

- Export Ratio:

91% - 100%

- OE Experience:

No

Product Name:Custom Injection Molding Plastic Parts Mould Accessories

Custom Injection Molding Plastic Parts Mould Accessories

Application

Contact Yize Mould Dongguan YIZE MOULD Co., LTD carbide punching pins Address: No.62, Jinghai East Road, Shatou District, Changan Town, Dongguan City, Guangdong Province, China TEL:+86-769-81888522 Email:dgyize@dgyize.com More information about carbide punching pins of YIZE,please visit our official website:

Product Description:

Custom injection molding plastic parts mould accessories

sisazhietyize| Mold base | LKM, DME, HASCO etc |

| Mold cavity and core steel | P20, LKM738, H13, S416, 1.2083,1.2085, 1.2311,1.2312,1.2343ESR, 1.2767, NAK80, etc. |

| Plastic material | ABS, ASA, PA-60GF, PBT, PC,PC/ABS, PE,PEI, HDPE, PMMA, PPS, PEEK, etc. |

| Hot runner | Moldmaster, Incoe, Yudo, Heitec, Gunther, Synventive, etc. |

| Hydraulic cylinder | Parker, AHP, HPS and so on. |

| Mold steel tolerance | +/-0.05mm |

| Standard parts | DME, Hasco, ect. |

| Mold life | 1,000,000 shots |

| Plastic injection moulding machine | Horizontal, Vertical |

| Custom | Custom manufacturing according to customer's drawing or samples |

| Plastic parts | Poly bag, 5-layer carton box |

Company Information

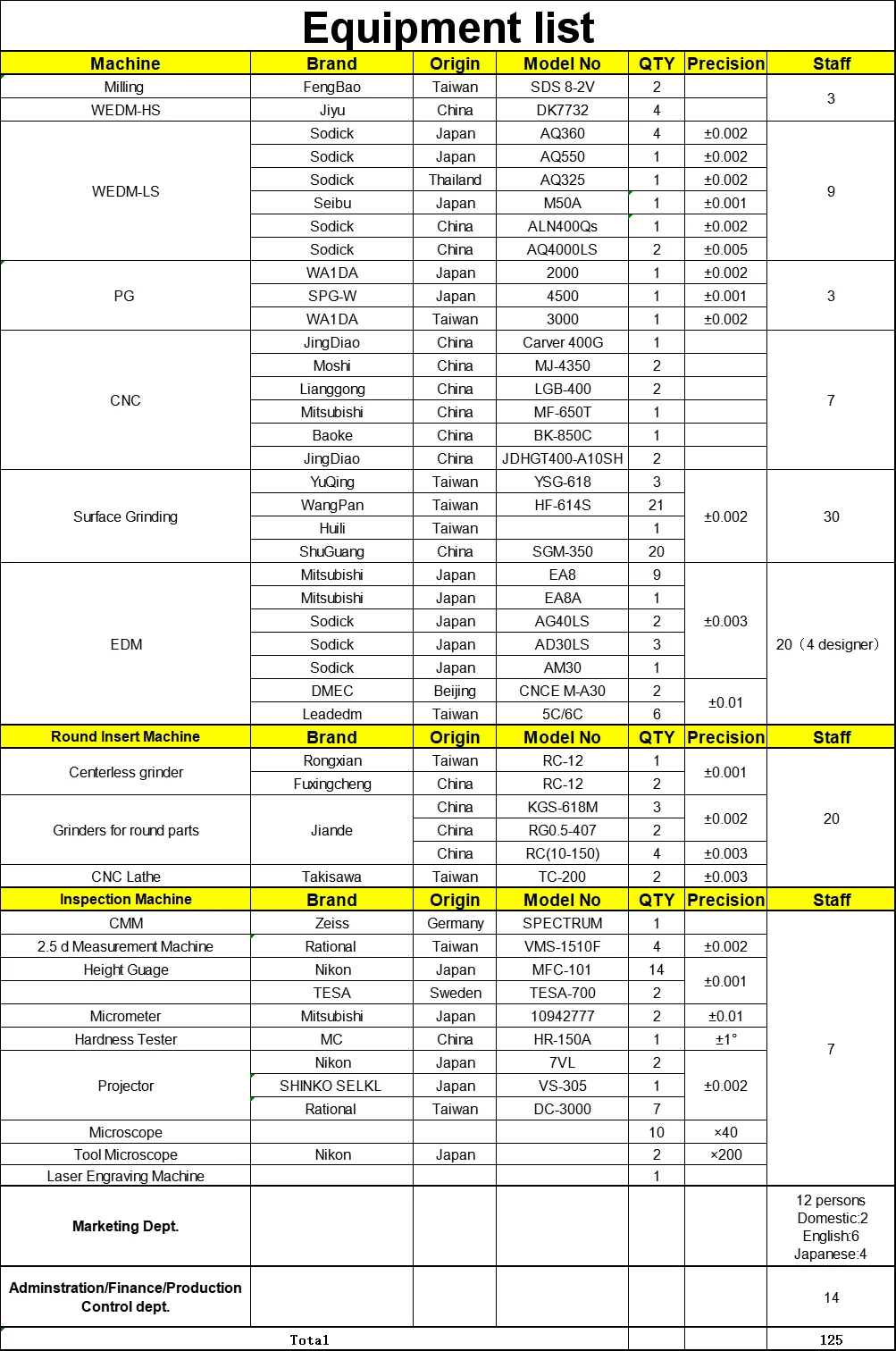

Dongguan Yize Mould Co.,Ltd. is a manufacturer specializing in producing precision mould parts for 15 years. Our quality products are used in many fields such as precision connector mould, plastic mould, punch mould, stamping mould, die casting mould,machinery,etc.The advanced technology and high quality service have obtained us a good reputation from customers at home and abroad.Yize adopts advanced manufacturing equipments and processing technology that from Japan.Our products are 100% exported, mainly Japan, United States, Southeast Aisa and Europe. We mainly make nonstandard parts as per drawing or supplied Grinding tolerance within 0.001mm,EDM and wire cut precision within 0.005mm,axiality within 0.002, circularity 0.0015mm, surface roughness Ra0.025,linearity 300mm within 0.002 are the production precision available

Advantages of Yize

Yize company takes "Overcoming difficulties and challenging crises" as its annual business slogan, enhances the crisis awareness of all employees, calls on all employees to work together, and increases the efforts of various education and training for employees as much as possible, and pays for the unforeseen difficulties in the future. For anyones efforts.

How to contact us,There are several ways1.Send your drawings to contact us ,

2.Or send the drawing to the following mailbox

3.Or contact me directly by WhatsApp +8613632038361

Quotation needs to provide product 3D drawings (stp/pre/igs) or samples, and inform customization requirements. The quotation time is generally within half an hour, and special circumstances will also be explained in time.

According to the modelsView More

Supplier Details

You May Like:

-

304 Stainless Steel Custom Turning Polished Mold C ...

Application: Dongguan YIZE MO ...

-

Professional Manufacturer Die Casting Aluminium Pa ...

Application: Contact Yize Mou ...

-

Tungsten Carbide Cold Heading Die For Punching Mou ...

Application: Contact Yize Mou ...

-

Companion Flange (For Auto Car Bus Truck Weld Yoke ...

Application: toyota

-

External Wastegate Flange

Application: GM, Volkswagen, ...

-

Chainwheel Of Auto

Application: standard

OEM No: Customi ...

-

Automobile Brass Bush , Copper Bush, Brass Connect ...

Application: Grate wall

-

Shroud For SCANIA

Application: SCANIA

Related Product Tags:

Battery Housing , center armrest , cnc machining precise part , cnc machining precise parts , combination shaft , companion flange , coolant flange , crankshaft flange , drive flange , flange , flange screws , flange sleeve , flange type plunger , flange fork , flange machining , flange manufacturer , flange york , flanges Didn't find what you are looking for?

Please send us Your Search Requirement, or you can Post a Buying Lead,

suppliers may contact you actively.

Please send us Your Search Requirement, or you can Post a Buying Lead,

suppliers may contact you actively.