Surface Treatment Of Precision Mold Parts Manufacturer Surface Titanium Plated Inserts

- Application: Changan

- Market Type:After Market

- FOB Price: USD 10

- Payment Terms: L/C, T/T, paypal

- Samples: Free

- Minimum Order: 1Piece/Pieces

Quick Details

-

Material:

other

-

Material Quality:

ISO900

-

material origin:

Sweden Japan and Germany

-

Gemeral precision:

0.005mm

-

Grinding precision:

0.001mm

-

EDM precision:

0.003mm

-

EDM angle clearness:

R0.03

- Place of Origin:

Dongguan

- Samples:

Free

- Delivery Time:

5-10 Working Days

- Packing:

Paper Of Box

- Delivery Port:

Shenzhen

- Max. Production Capacity:

1000pieces A Week

- Export Ratio:

81% - 90%

- OE Experience:

No

Product Name:Surface Treatment Of Precision Mold Parts Manufacturer Surface Titanium Plated Inserts

Surface Treatment Of Precision Mold Parts Manufacturer Surface Titanium Plated Inserts

Application

Changan

Product Description:

Surface treatment of precision mold parts manufacturer surface titanium plated inserts

precision mold parts

yizali2iL

Dongguan precision mold parts customization choose Yize mould. We have a complete set of professional mold design team and mature production, assembly and trial die technology to provide customers with professional whole die design and overall technical solutions.

Dongguan Yize Mould Co.,Ltd. was established on 1st January 2007 with 125 employees currently. As a professional precision machinery equipment parts manufacturer, Yize company attaches great importance to the business policy of Customer First,with supreme quality and short lead time,which is deeply trusted by customers in the field of automotive,electronics,aerospace,medical technology,jig& fixture and mould manufacturing.

With 15 years of professional knowledge and unique manufacturing range, Yize company is capable of the following production processes as turning,milling,grinding,EDM,WEDM,PG and designing&assembling sets of mechanical components and mould components according to customers need.

OEM PRODUCTION PROCESS

1.Order:Issue the drawings as per customers needs

2.Procedure: Technicians formulate detailed manufacturing procedure based on drawing requirement and procedure reviews

3.Production: Production personnel manufacture the products according to the drawings and manufacturing procedure sheet

4.Inspection: Full inspection by QC and do the test report as per customers advice

5.Package: Proper packaging as per customers requirement to avoid damages during transportation

6.Delivery: Speedy on-time delivery to make a win-win situation

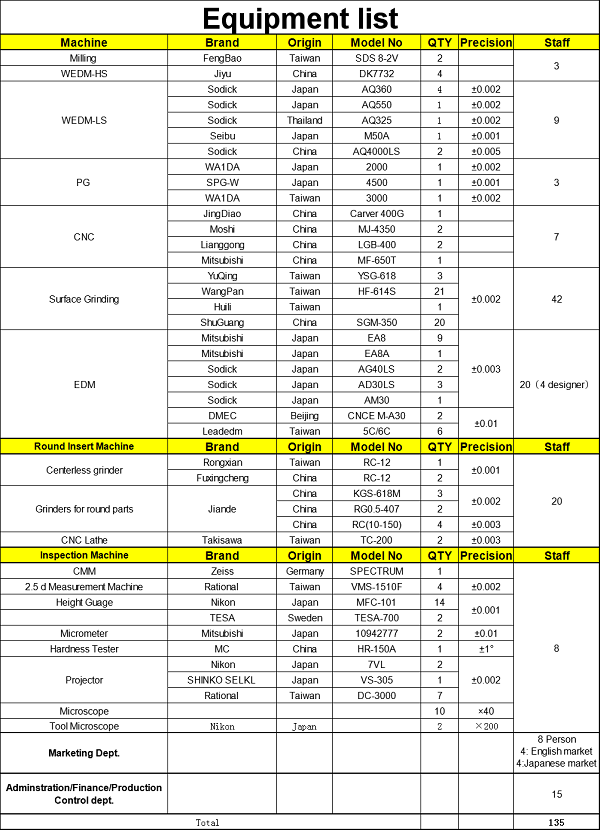

Our equipment list:

FAQ

Q: How can I get a sample ?

A: Customer can get a sample by sending 2D/3D/PDF drawing .

UPS, OCS, EXPRESS, DHL, FEDEX are available for shipment.

Q: Whats your lead time ?

A: 7-15 days normally, depends on the quantity and complexity of the components.

Q: What information should I provide to get a quotation ?

A: Material, quantity, dimension, tolerance; CAD drawing will be best if convenient.

Q: What about after sale service?

A: Spare parts which is non-man made damage will be offered replacement for free within 90 days after shipment, and you can contact us any time if need help.

Q: How about your quality control

A: 1. Every processing technician mastered the inspection skills in order to check each dimensions during machining;

2. After the completion of processing, parts will be transferred to the QC department for full dimension inspection.

3. Double-check before packing to make sure no defective products will be released.

Q: Do you have the surface finishing capability?

A: Yes, and divided into the following sections

1. Grain surface treatment --- polishing, fire pattern, erosion, sand blasting

2. Electroplating treatment -- -nickel plating, zinc plating, chrome plating, titanium plating, chrome plating , flash chrome plating.

3. Nano coatings - TIN, TICN, DLC, TIAIN, CrAIN, CrN

Send us drawings, we will quote to you soonest.

Thanks & Best regards

Dongguan YIZE MOULD Co.,LTD

precision mold parts Address: No.62, Jinghai East Road, Shatou District, Changan Town, Dongguan City, Guangdong Province, China

yizali2iL

Supplier Details

You May Like:

-

Apple Machine Spare Part/Oem Mould Accessories In ...

Application: Changan

-

Punch Mold Parts/Japan Machine Part With Customiza ...

Application: Changan

-

Japan Machine Spare Part/Carbide Punches Oem

Application: Changan

-

solid tyre mould

Application: all kind of soli ...

OEM No: 8480790 ...

-

Magnetic Roof Hat (Magnetic Roof Top Magnetic Roof ...

Application: toyota

-

100% Genuine Zotye Spare Parts Wheel Opening Mould ...

Application: Zotye

OEM No: 66850-D ...

-

HYUNDAI ATOS FOG LAMP COVER 86611-06020

Application: USED FOR HYUNDAI ...

OEM No: 86611-0 ...

-

RENAULT Truck EBS Modulator 5010457556

Application: RENAULT PREMIUM ...

OEM No: 5010457 ...

-

Plastic Over Molding Part

Application: Universal

Related Product Tags:

air conditioner mold , air conditioner mould , amplifier module , bearing mould , blower control module , bumper mold , automobile bumper mold , auto bumper mold , auto bumper mould , rear bumper mould , plastic bumper mould , automobile bumper mould , bumper mould , car bumper mould , front bumper mould , car bumper mold , casting mould , electronic control modulePlease send us Your Search Requirement, or you can Post a Buying Lead,

suppliers may contact you actively.