High Durability Precision Tungsten Carbide Punch And Die Component With WEDM Processing

- Application: Dongguan YIZE MOULD Co.,L...

- Market Type:After Market

- FOB Price: USD 1.6

- Other Price Term: EXW

- Payment Terms: L/C, T/T

- Samples: Free

- Minimum Order: 100PCS

Quick Details

-

Material:

Metal

-

Material Quality:

ISO900

- Place of Origin:

China

- Samples:

Free

- Delivery Time:

7-15 Days After T/T 30% Deposit

- Packing:

Each Part Will Be Coating Oiling To Form A Protective Coating Against Rust, Corrosion, Etc,Then Packed With Pearl Cotton To Shake Proof ,After That P

- Delivery Port:

SHENZHEN PORT

- Max. Production Capacity:

10000 Piece/Pieces Per Day

- Export Ratio:

91% - 100%

- OE Experience:

No

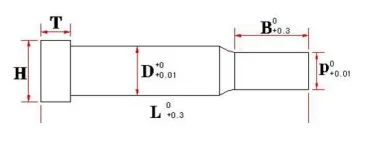

Product Name:High Durability Precision Tungsten Carbide Punch And Die Component With WEDM Processing

High Durability Precision Tungsten Carbide Punch And Die Component With WEDM Processing

Application

Dongguan YIZE MOULD Co.,LTD Address: 3/F, Factory Building, No.62, Jinghai East Road, Shatou District, Changan Town, Dongguan City, Guangdong Province, China TEL:+86-769-81888522 Email:alisa.chen@dgyize.com More information about the precision stamping mold parts of YIZE,please visit our official website:

Product Description:

Precision punch and die component customized processing platform in China

yjoisoehahh

| Product details |

|

| Type |

Tapered Pin Set, Locking Block Set, Precision Carbide Punch, Punch And Die, Etc. |

| Material Details | SKD11. SKH51. SKD61.ASP CARBIDE..More materials |

| Common shapes | T type, A type, square type, special shape, customized according to customer drawings |

| Processing technology |

Lathe processing / hardness processing / grinding machine processing / surface treatment |

| Customized | Available |

| Payment | T.T Western Union , Paypal |

| Production address | Dongguan, Guangdong, China |

| Delivery Time | Stocks Now(Or 7-15 Days) |

| Transport | DHL,Fedex,UPS,TNT or By Sea |

| Product Keywords | Punches, punches, tungsten steel punches, CNC punches, carbide punches, ASP-23 punches, powdered high-speed steel punches, SKH51 punches, SKD11 punches, DC53 punches, and mother-in-law punches , Shaped punching needles, guided punching needles, guiding needles, hole punching needles, forming punches, oval punches, square punches, hexagonal punching needles, special-shaped punching needles, non-standard punching needles, etc. |

The smallest outer diameter value can reach 0.001mm, and the outer diameter tolerance can reach 0.001mm. The outer diameter and inner hole finish can be mirror-finished. The actual tolerance is processed according to customer requirements. Other requirements: Titanium plating, lettering, etc. can be made according to customer requirements.

Yize adopts advanced manufacturing equipments and processing technology that from Japan.Our products mainly sold to foreign countries like Germany, United States, Japan, Italy, Singapore, Thailand and Malaysia etc.We can manufacture the products according to customers' demands with reference to world brand as well as international industry standards like GB,JIS,DIN and AISI.Our products precision:size tolerance±0.001mm,co-axiality within 0.002, circularity 0.0015mm, surface roughness Ra0.025,linearity 300mm within 0.002

Our strengths:Yize mould through 15 years of exploration, each process with more than 10 years of experience at all levels of senior technicians, to ensure that each process produce 100% good products.yjoisoehahhAll the raw materials of Yize mould are imported from Datong, Hitachi and yishengbai of Japan, and the second tempering of vacuum heat treatment and ultra deep cold treatment are adopted. The acid-base resistance of the product is more than three times higher than that of the same industry.With an excellent team with 15 years of mould manufacturing experience, Yize mould can fully meet the needs of the international market.

Yize Mould perfect service system, short delivery time, from order to delivery only 7-10 production days, so that customers enjoy high-quality service.

Yize Mould promises that technology innovation and product development to provide a variety of mould components including precision automatic machine components,core pins and sleeves,precision mould partsand precision plastic parts etc.

According to the modelsView More

Supplier Details

You May Like:

-

Mold Die Punch And Die Tooling High Quality Tungst ...

Application: Dongguan YIZE MO ...

-

Bushing Wall Plug Socket Power Socket Plastic Inje ...

Application: Dongguan YIZE MO ...

-

Punching Mold Shaping Mode Precision Punch And Die

Application: Dongguan YIZE MO ...

-

solid tyre mould

Application: all kind of soli ...

OEM No: 8480790 ...

-

Magnetic Roof Hat (Magnetic Roof Top Magnetic Roof ...

Application: toyota

-

100% Genuine Zotye Spare Parts Wheel Opening Mould ...

Application: Zotye

OEM No: 66850-D ...

-

HYUNDAI ATOS FOG LAMP COVER 86611-06020

Application: USED FOR HYUNDAI ...

OEM No: 86611-0 ...

-

RENAULT Truck EBS Modulator 5010457556

Application: RENAULT PREMIUM ...

OEM No: 5010457 ...

-

Plastic Over Molding Part

Application: Universal

Related Product Tags:

air conditioner mold , air conditioner mould , amplifier module , bearing mould , blower control module , bumper mold , automobile bumper mold , auto bumper mold , auto bumper mould , rear bumper mould , plastic bumper mould , automobile bumper mould , bumper mould , car bumper mould , front bumper mould , car bumper mold , casting mould , electronic control module Didn't find what you are looking for?

Please send us Your Search Requirement, or you can Post a Buying Lead,

suppliers may contact you actively.

Please send us Your Search Requirement, or you can Post a Buying Lead,

suppliers may contact you actively.