High Capacity Dry Powder Briquette Machine/Dry Powder Briquette Machine

- Application: Handling Materials: Pebbl...

- Market Type:After Market

- FOB Price: USD 10000

- Payment Terms: L/C, T/T

- Samples: Not Available

- Minimum Order: 1Set/Sets

Quick Details

- Place of Origin:

Fote

- Samples:

Not Available

- Delivery Time:

25 Working Days

- Packing:

Export Package Standard. Large Part Is Non-Packed, Small Parts Are In Wooden/ Metal Box Package

- Delivery Port:

Qingdao Dalian Tianjin

- Max. Production Capacity:

2200t/H

- Export Ratio:

91% - 100%

- OE Experience:

No

Product Name:High Capacity Dry Powder Briquette Machine/Dry Powder Briquette Machine

High Capacity Dry Powder Briquette Machine/Dry Powder Briquette Machine

Application

Handling Materials: Pebble, calcite, granite, quartz, concrete, dolomite, bluestone, iron ore, limestone, iron ore, coal gangue, construction waste, ferrosilicon, basalt, sandstone, rocks, ore, glass, cement clinker and some metal.

Product Description:

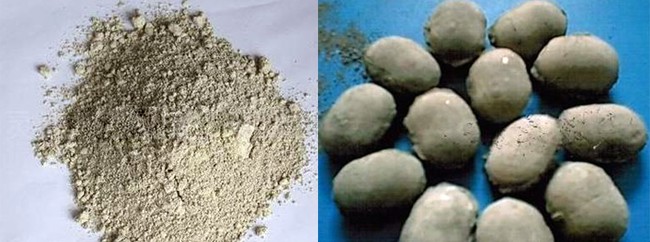

Dry powder briquette maker is mainly used for ball making with waste lime powder. In the usage of the machine,there is the need to control the operation of the device. The equipment is easy to operate and has high efficiency. It is currently recognized by the uses. Due to the scientific research of the related institutions in metallurgy industry, this problem has been solved, namely, to use the high-pressure powder ball press machine to press the powder into block for smelting.

Dry Powder Briquette Machine/High Capacity Dry Powder Briquette Machine is mainly used to make the coal powder, iron powder, coke, aluminum powder, scrap iron, sinter, toner, carbon dust, slag, gypsum, tailings, sludge, kaolin, activated carbon, coke breeze and other powders and wastes be widely used in refractory, power plants, metallurgy, chemical industry, energy, transport, heating and other industries. The molding materials after the processing of ball press machine are energy saving and easy to transport, improving the utilization rate of waste materials and having good economic and social benefits.

Based on the production experience of briquette in the plant, the dry powder briquette press is designed and manufactured with the foreign equipment framework improved, according to the actual experience of users in the production; our plan summarized the advantages and disadvantages, and innovates unceasingly. The briquette press of our plant has be granted six national patents, which keep leading in designing, materials selection, fine process, monitoring means, whole machine strength and performances in the trade.

Dry Powder Briquette Machine/High Capacity Dry Powder Briquette Machine adopts thin oil cycle lubrication ,it has two kinds of lubrication system: One is the oil pump shaft with the driving, called the integral lubricating system; The other is the oil pump drive alone lubrication system. Most of the crusher machine is equipped with oil pump drive alone the lubrication system. In this system, before starting the crusher for lubrication, it is a strong adaptability,and a lubricating system which is easy to control the oil temperature, the amount of oil and oil pressure to ensure lubricating system and the normal work of the crusher is very important.

Henan Fote Heavy Machinery Co., Ltd. has standardized heavy industrial factory workshop equipped with modern professional production of a variety of large, medium-sized metal processing, welding, assembly equipment, has a highly qualified professional and technical team and experienced production team of workers. The company is equipped with state-of-the-art computer-aided design system and computer simulation test system, with advanced testing and detection methods, products strictly in accordance with ISO9001: 2000 quality management system standard full implementation of quality supervision and management to ensure that the design, development, production and after-sales service aspects of quality. Welcome to visit and purchase.

Supplier Details

You May Like:

-

High Performance Automatic Dry Powder Briquette Pr ...

Application: Raw Materials:Co ...

-

Advanced Design Manganese Powder Briquette Machine ...

Application: Raw Materials:Co ...

-

Dry Powder Briquette Machine With Competitive Pric ...

Application: Raw Materials:Co ...

-

Companion Flange (For Auto Car Bus Truck Weld Yoke ...

Application: toyota

-

External Wastegate Flange

Application: GM, Volkswagen, ...

-

Chainwheel Of Auto

Application: standard

OEM No: Customi ...

-

Automobile Brass Bush , Copper Bush, Brass Connect ...

Application: Grate wall

-

Shroud For SCANIA

Application: SCANIA

Related Product Tags:

Battery Housing , center armrest , cnc machining precise part , cnc machining precise parts , combination shaft , companion flange , coolant flange , crankshaft flange , drive flange , flange , flange screws , flange sleeve , flange type plunger , flange fork , flange machining , flange manufacturer , flange york , flangesPlease send us Your Search Requirement, or you can Post a Buying Lead,

suppliers may contact you actively.