Yanma 4TNE106 4TNV106 Diesel Engine Crankshaft

- Application: all

- Market Type:After Market

- Price: US $35 - 200 / Piece

- Payment Terms: T/T, Western Union,MoneyGram

- Minimum Order: 10 Pieces

Quick Details

-

Supply Ability:

10000 Piece/Pieces per Month

- Packing:

Inner packing: Waterproof paper packing; Outer Packing: Export carton packing with/ without Pallet; Customized packing is available.

- Delivery Port:

Guangzhou, Shenzhen, Ningbo, Shanghai

- OE Experience:

No

Product Name:Yanma 4TNE106 4TNV106 Diesel Engine Crankshaft

Yanma 4TNE106 4TNV106 Diesel Engine Crankshaft

Application

all

Product Description:

Yanma 4TNE106 4TNV106 Diesel Engine Crankshaft

Details for Yanma 4TNE106 4TNV106 Diesel Engine Crankshaft:

| Name | Yanmar 4TNE106 4TNV106 crankshaft |

Engine Model | 4TNE106 4TNV106 |

| No.Cylinder | 4-cylinder |

| Application | Yanmar diesel engine |

| OEM No. | 123900-21000 |

Crankshaft mechanical character:

Material: | Forged steel |

Strength of extension | ≥1080 MPA |

Elongation | ≥12% |

Strike | ≥78 J/CM2 |

Hardness | HRC55-58 |

Chemical component compare list:

AISI 4340 | ||||||||

C ≤ | Si ≤ | Mn ≤ | P ≤ | S ≤ | Cr | Ni | Mo | |

0.38-0.43 | 0.15-0.35 | 0.6-0.8 | 0.035 | 0.04 | 0.7-0.9 | 1.65-2.0 | 0.2-0.3 | |

42CrMo4 | ||||||||

0.38-0.45 | 0.4 | 0.6-0.9 | 0.035 | 0.035 | 0.9-1.2 | ≤ 0.03 | 0.15-0.3 | |

Pictures for Yanma 4TNE106 4TNV106 Diesel Engine Crankshaft:

Advantage of our crankshaft:

1. Our crankshaft use the highest quality E4340 Aircraft quality Cr-Ni-Mo alloy billet steel.

2. Triple heat treated for extreme strength, toughness & durability.

3. Ion-plasma nitride for superior journal surface hardness & wear resistance.

4. Heat treatment, quenching Increasing the strength (surface treatment,

e.g. Induction hardening, fillet rolling or shot peening, etc.)

5. Dimensional measurement,Full NDT inspection (Magnaflux and Hardness),ultrasonic testing,

crack detection and material testing.

6. Fatigue strength testing

7. Torsion and bending fatigue testing

About our quality control:

We have passed quality control certification system of ISO9000,TS16949 which are main quality certificate.

Quality Control equipments include Spectrometer, Microscope, Durometers, Magnetic particle crack detectors,

Perfilometer, Roughness test machine, Residual stress inspection etc.applied on every production step.

HC Crankshafts are guaranteed for 12 months after arming in engine.If in this period the crankshaft is broken,

we will one compensable three.

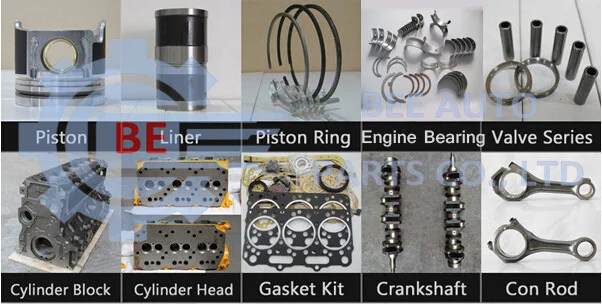

More engine parts we can supply for most vehichles:

Stocks for following Japanese multi-function engine parts:

| Yanmar: | 3TNE84, 3TNE88, 4TNE88, 4TNA94, 4TNA98, 4TNV98 |

| Kubota: | D1462-DI, F2302-DI, F2803-B, V3300-B, V3300-B. V3300-DIE, V3300-TIE |

| Shibaura: | N844, N844L, N844T |

| Isuzu: | 3AE1, 3KB1, 3KC1, 3KC2, 3KR1, 3KR2, 3/4LB1, 3/4LC1, 3LD1, 4FB1, 4FC1, 4FD1, 4FE1, 4FG1, 4FG1T, 4JB1, 4JG2, 4LE1, 4LE2, D201 |

| Komatsu: | 4D94, 4D94E, 4D95A, 4D95K, 4D95LE-3, 4D95LE, 4D95S, 4D95T, 4D98E, S4/6D95T, 4D105-3, 4D120, 4D130, 6D105-1, 6D105, 6D155, S6D95, S6D102, S6D105-3, S4/6D105-5, S6D108, S6D108, S6D110-2, S6D110-3, S6D110, S6D125, S6D140, S6D170, NH220, NH250 |

| Mazda: | WL B2500, S2 E2200, XA E2500, XB E2700, HA E3000, XA T2500, HA T3000, VS T3000, T3500, SL T3500, TF T4000, ZB T4100, TM T4500 |

| Mitsubishi: | 4DQ5, K3B, K3F, K3H, K3M, K4C, K4D, K4E, K4E-DI, K4F, K4H, K4M, K4N, K4Q, 4DQ7, L3C, S3E, S3L2, S4E, S4E2, S4F, S4L, S4L2, S4L2-T, S4Q2, S4Q2-1, S4S, S6E2, S6KT, S6SD |

| Nissan: | BD30, H20, K21, K25, SD22, SD23, SD25, TD23, TD25, TD25T, TD27, TD27T |

| Toyota: | 1DZ-2, 1DZ, 1Z, 2H, 2J, 2Z, 2Z-N, 12Z, 13Z, 14Z |

Our quality control and factory:

1.we strictly adhere to the GB1148-82, JB3932-85 Criterion

2.100000km guaranteed.

3.send sample for checking before delivery.

Contact us:

Chat Now Contact Supplier

Supplier Details

You May Like:

-

Crankshaft BENZ OM314 3140303202 3140305502 314030 ...

Application: Crankshaft BENZ ...

OEM No: 3140303 ...

-

Crankshaft Mitsubishi 6G74 MD305941

Application: Mitsubishi 6G74

OEM No: MD30594 ...

-

TOYOTA 11Z Crankshaft ,12Z Crankshaft , 13Z Cranks ...

Application: TOYOTA 11Z

OEM No: Cranksh ...

-

China Yanma 4tnv84 4tnv84t Diesel Engine Crankshaf ...

Application: All

OEM No: 4tnv84 ...

-

ISUZ 4BC2 Diesel Engine Crankshaft

Application: all

-

Used Toyota 3Y 4Y Diesel Engine Crankshaft

Application: all

-

Brand New HYUNDAI KIA Crankshaft D4EA/D4EB 16V 231 ...

Application: KIA HYUNDAI

OEM No: 23110-2 ...

-

CRANKSHAFT 1005011FA090

Application: for JAC SUNRAY

OEM No: 1005011 ...

-

CHEVROLET SAIL Crankshaft Lower Bearing (Oversized ...

Application: Chevrolet

OEM No: 2410255 ...

Related Product Tags:

crank , crank case , crankcase , bell crank , toyota crank case , crank shaft , crankshaft sensor , bearing set crank shaft , forged crank shaft , forging crank shaft , Auto Rear Crankshaft , BMW Crankshaft , BENZ Crankshaft , Auto Engine Crankshaft , Audi Crankshaft , Chrysler Crankshaft , cat Crankshaft , Casting CrankshaftPlease send us Your Search Requirement, or you can Post a Buying Lead,

suppliers may contact you actively.