Cylinder Head For HYUNDAI CARS G6BA, 2.5 / 2.7 V6 24V DOHC Engine Cylinder Head

- Application: For HYUNDAI CARS G6BA, 2....

- OEM No/Model: G6BA, 2.5 / 2.7 V6 24 ...

- Market Type:After Market

- FOB Price: USD Negotiation

- Other Price Term: CIF CFR EXW

- Payment Terms: L/C, T/T

- Samples: Charge

- Minimum Order: 10PCS

Quick Details

-

Material:

Cast Iron

- Place of Origin:

Made in China

- Samples:

Charge

- Delivery Time:

30-45days

- Packing:

- Neutral Export Box - Strong Packing With Polyfoam Protected

- Delivery Port:

Shanghai

- Max. Production Capacity:

1000 Piece/Pieces / Month

- Export Ratio:

81% - 90%

- OE Experience:

No

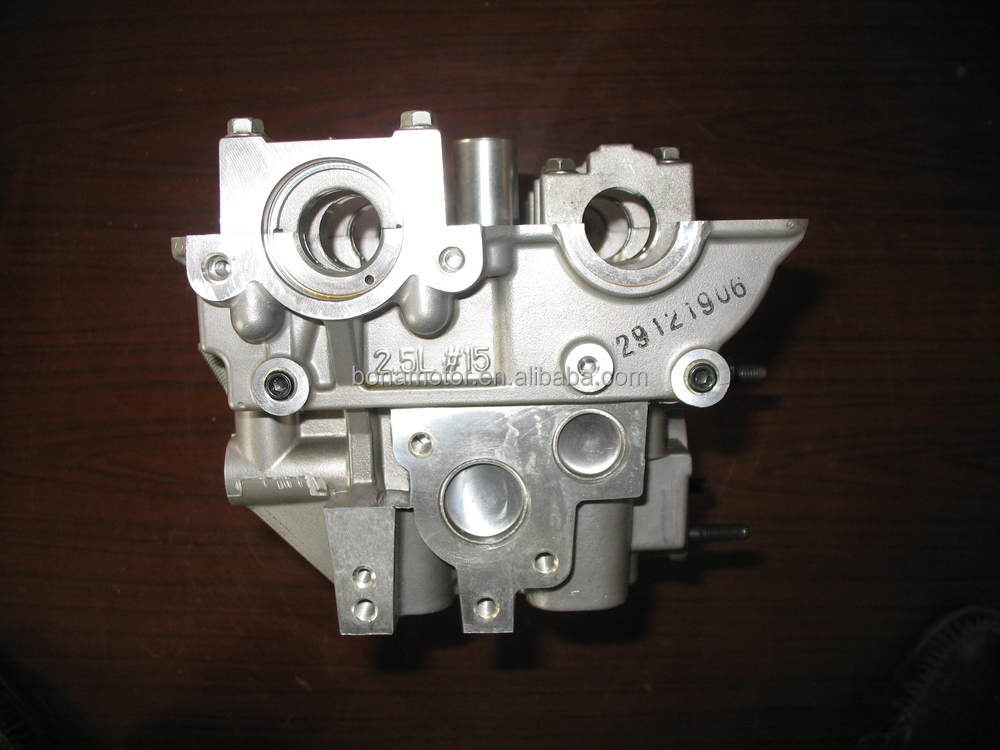

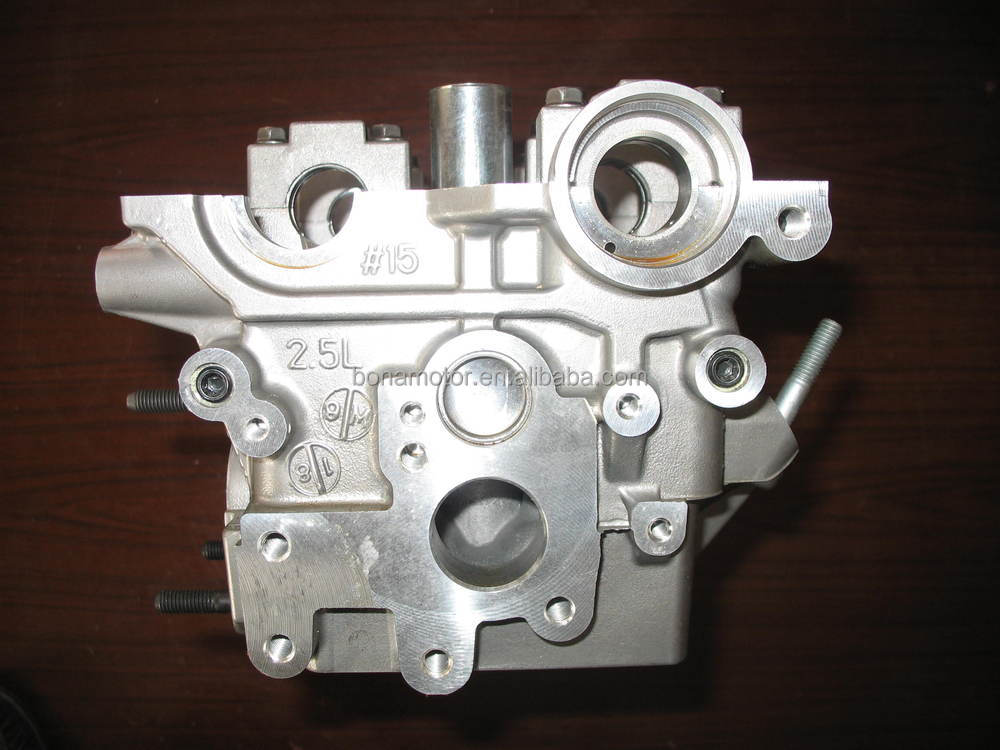

Product Name:Cylinder Head For HYUNDAI CARS G6BA, 2.5 / 2.7 V6 24V DOHC Engine Cylinder Head

Cylinder Head For HYUNDAI CARS G6BA, 2.5 / 2.7 V6 24V DOHC Engine Cylinder Head

Application

For HYUNDAI CARS G6BA, 2.5 / 2.7 V6 24V DOHC Engine

Product Description:

OEM No/Model: G6BA, 2.5 / 2.7 V6 24V DOHC

ylinder head for HYUNDAI CARS G6BA, 2.5 / 2.7 V6 24V DOHC engine cylinder head

PRODUCT:

- Description: Cylinder Head , engine cylinder head, engine head, auto head

- Application: for HYUNDAI CARS G6BA, 2.5 / 2.7 V6 24V DOHC engine

-Remark:

SONATA 2001-2006

SANTA FE 2001-2006

TUSCON 2001-2006

TIBURON 2001-2006

KIA OPTIMA 2001-2006

- Engine type: G6BA, 2.5 / 2.7 V6 24V DOHC engine

- Material: casting iron

- OEM#:

- Warranty: 1 year or 40000kms

Certificate: ISO9001 TS16949

PACKING: 1pc / strong multi-ply wooden box

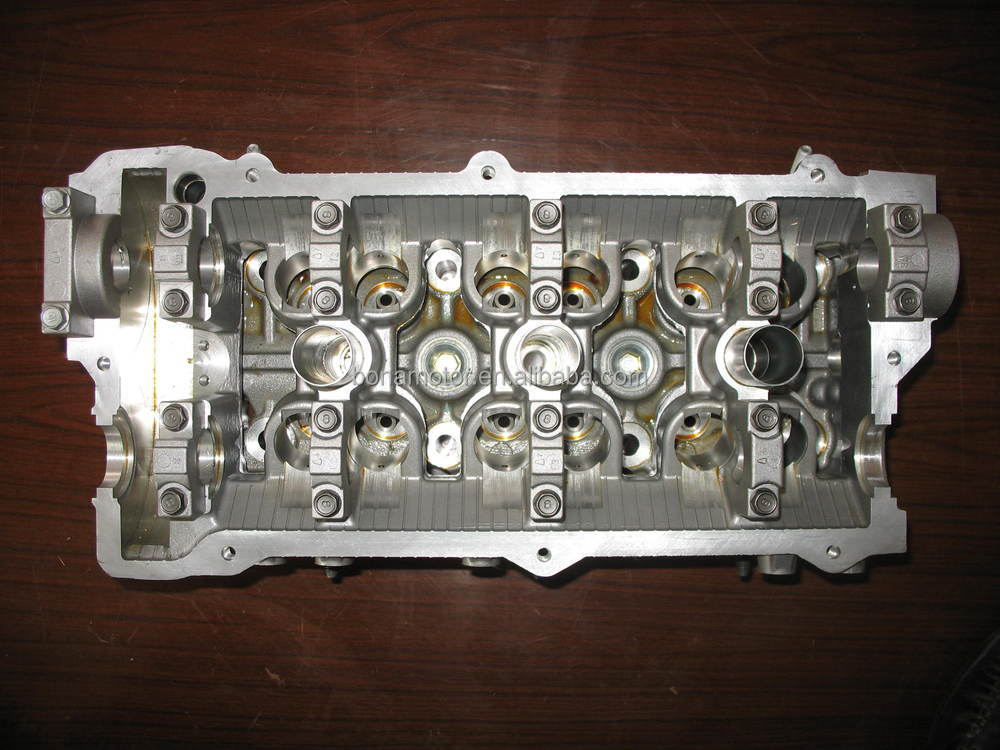

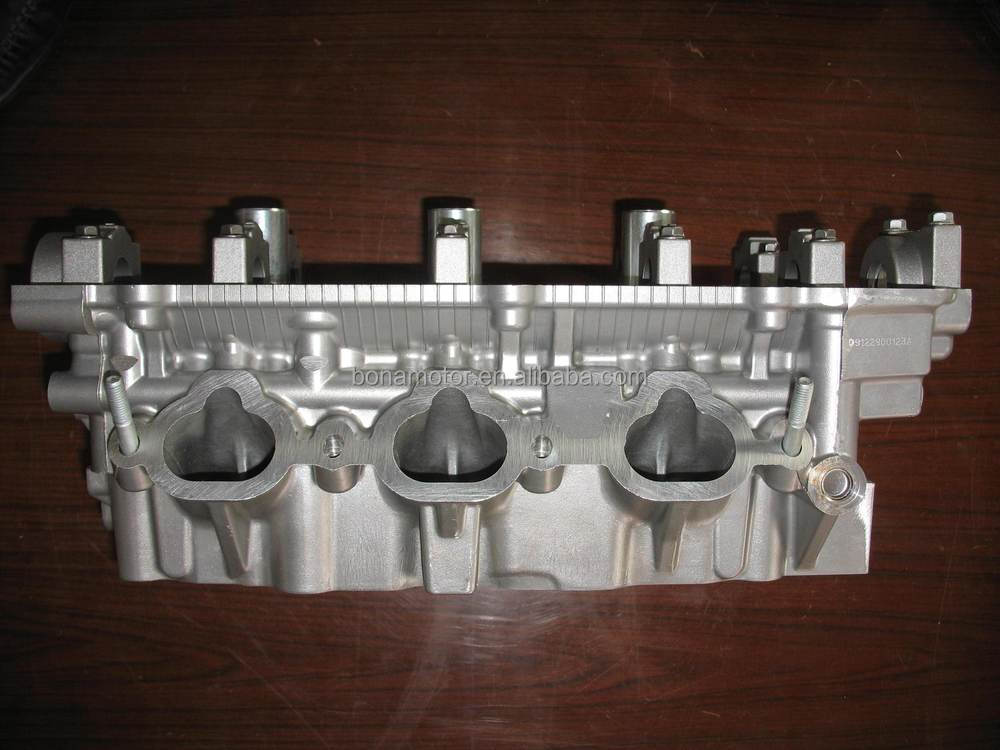

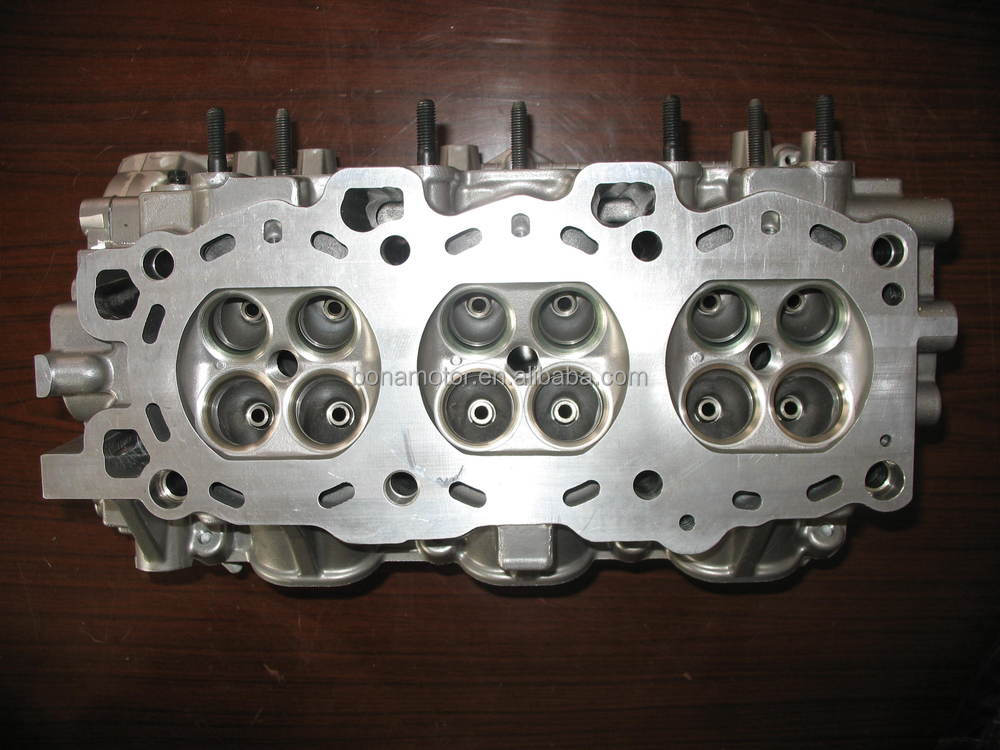

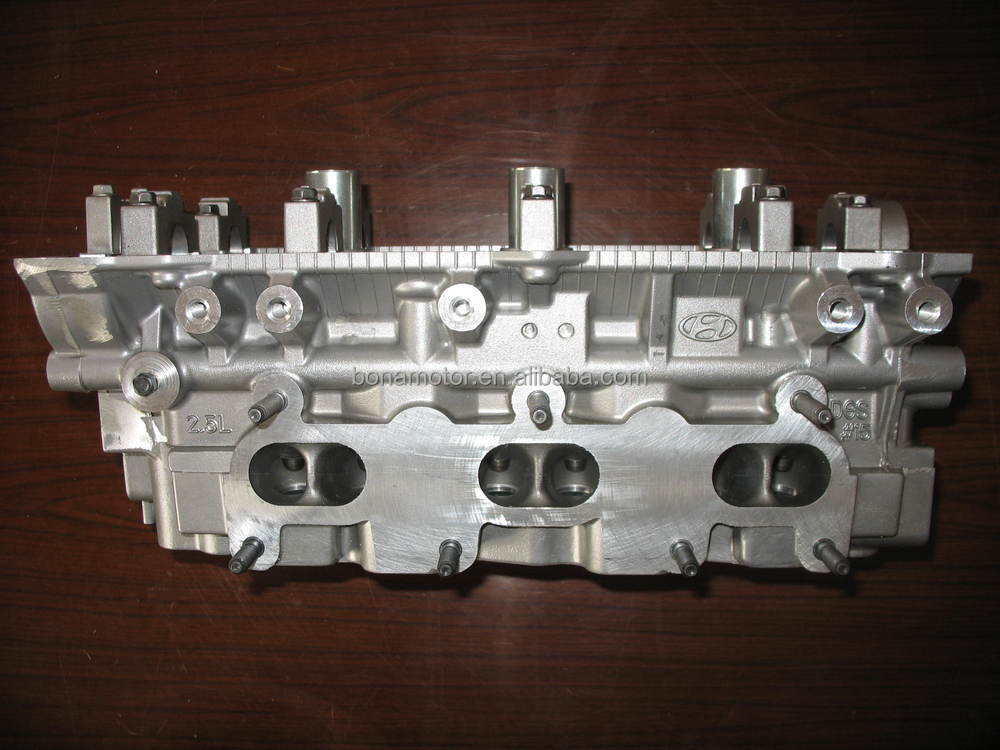

PICTURE:

*

*

Supplier Details

You May Like:

-

High Quality 1 HZ Complete Cylinder Head For Toyot ...

Application: For Toyota 1HZ

OEM No: 1HZ

-

Cylinder Head PEUGEOT DV6 ATED4 AMC908596 0200.EH

Application: PEUGEOT DV6 ATED ...

OEM No: AMC9085 ...

-

Cylinder Head For DETROIT 6V92 3-92 5149877 Cylind ...

Application: DETROIT 6V92 3-9 ...

OEM No: 5149877

-

Nissan KA24-DE Cylinder Head 11040-VJ260

Application: Nissan

OEM No: 11040-V ...

-

Cylinder Head Kubota 4D82

Application: Kubota 4D82

OEM No: Kubota ...

-

Cylinder Head Nissan YD25 11040-5M300

Application: Nissan YD25, 2.5 ...

OEM No: 11040-5 ...

-

Cylinder Head VW 1.9TDI AMC908703

Application: VW AGP/AHF/AGR/A ...

OEM No: 0381033 ...

-

4Y 491Q 11101-73020 Cylinder Head 1110173020 11101 ...

Application: Toyota Hiace

OEM No: 1110173 ...

-

Cylinder Head

Application: for MG 350

OEM No: 3005293 ...

Related Product Tags:

Chery Aluminum Cylinder Head , PEUGEOT Cylinder Head , Petrol Cylinder Head , Peugeot Dw8 Cylinder Head , Quality Cylinder Head , QQ Cylinder Head , RENAULT Cylinder Head , RF Cylinder Head , RF R2 Cylinder Head , Pride Cylinder Head , TR Cylinder Head , Toyota 1kd 2kd cylinder head , Toyota 2kd Cylinder Head , Tico Cylinder Head , Steyr Cylinder Head , Sheet Cylinder Head , S6KT Cylinder Head , Shanghai Volkswagen Cylinder HeadPlease send us Your Search Requirement, or you can Post a Buying Lead,

suppliers may contact you actively.