China Top Wear Sensors Car Brake Pads D836&D687&d555

- Application: all

- Market Type:After Market

- Price: US $1 - 5 / Set

- Payment Terms: L/C, D/A, T/T, D/P, Western Union,MoneyGram

- Minimum Order: 50 Sets

Quick Details

-

Supply Ability:

300000 Set/Sets per Month

-

Delivery Details:

30-45 days after the deposit payment

- Packing:

1.Box packing:Our brand box or yours. 2.Outer packing: ten sets of brake pads in one carton box.

- Delivery Port:

Shanghai/Ningbo

- OE Experience:

No

Product Name:China Top Wear Sensors Car Brake Pads D836&D687&d555

China Top Wear Sensors Car Brake Pads D836&D687&d555

Application

all

Product Description:

Contact Info:

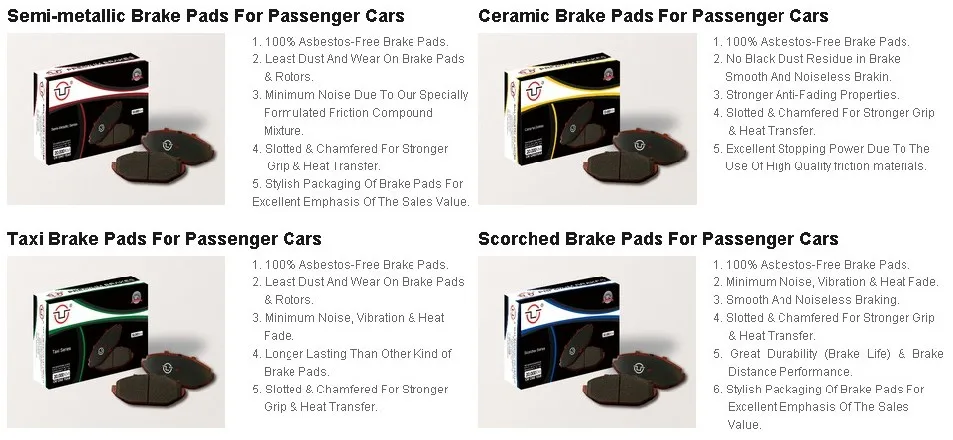

Features:

1.100% Asbestos-Free Formulation.

2.Offer Extended Life And Minimum Disc wear.

3.Optimize The Performance Of Vehicle's Braking System.

4.Deliver High Stopping Power, Reliability And Safety.

5.Feature A Minimum Brake-in & Bedding-in Period

6.Stylish Packaging For Excellent Emphasis Of The Sales Value.

Specifications:

| MOQ | 50 Sets |

| Delivery | 30-45 Days after the deposit |

| Port | Shanghai,Ningbo,Qingdao |

| Color | Black,Red,Blue,Grow,Green,or Your Favorite |

| Packings | ten sets in one carton box with our brand or yours |

Premium Steel Backing Plates For Passenger Cars Brake Pads

Bull brake backing plates are produced by high quality steel, which has a strong ability to hold the braking system together so it can work properly; the friction materials are attached to one side of the brake backing plate. Our brake backing plates are all meet the international standards, including the hardness, smoothness, and thickness, which will give a steady and comfortable braking; it can make you safe all the way along.

Standard Brake Shims For Passenger Cars Brake Pads

Bull brake pad are equipped with premium brake shims, we have different kinds of brake shims, as showed in pictures, they are made up of thin metal, rubber or fabric, which adhesive pads that fit between the brake pad and the brake caliper to correct small differences that sometimes lead to noise. These brake shims are mainly used to keep the noise down and any rattles to a minimum. Not all brake pads come with shims as they aren’t required and function perfectly without needing them.

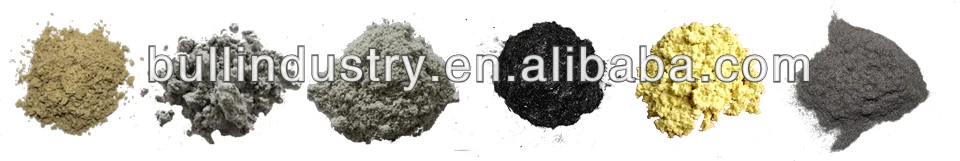

High Quality Friction Materials For Passenger Cars Brake Pads

The tribological application of phenolic resin-basd friction materials is usually limited owing to the relatively poor stability and wear resistance. Therefore, we choose to incorporate various reinforcing and filling constituents such as steel fibers, copper fibers, carbon fibers, Dupont aramid, and ceramic fibers, mineral wool, carbon coke, etc into phenolic resin-based friction composites for the purpose of increasing the stability and wear resistance.

The Advanced Production Technique For Passenger Cars Disc Brake Pads

All automatic mixers can help us to prepare standard raw materials, which will make the exact component of each kind material. We changed to one-step press machines, these advanced machines will not only increase our work efficiency and production ability, but also can make the appearance of brake pads much better than old machines. A complete production line of grinding, powder coating, riveting and coding, etc will make our brake pads in best quality and appearance.

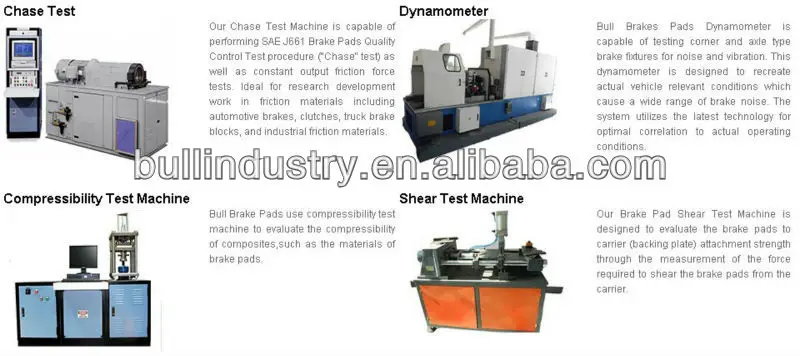

High-Performance Test Machines For Car Brake Pads

New Packings For Passenger Car Brake Pads

1. New Blister Packing of Brake Pads

2. Stylish Packages of Car Brake Pads With Different Types.

3. Stronger and Harder Paper Box With Beautiful Printing

4. Up-Market Printing With An Excellent Market Value.

5. Ten Sets of Brake Pads In One Carton Box Packed By Qualified PE Tape

6. Pallet Size: 120cm*80cm*80cm or 105cm*105cm*105cm, depends on you.

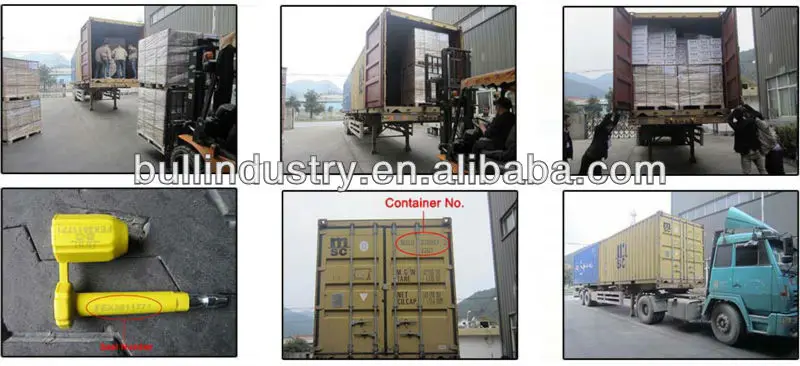

Safely And Timely Shipments For Passenger Cars Disc Brake Pads

We worked with our shipping agency more than ten years, each year we export about 300 containers through them, we treat every client equally, that is to make each order shipped safety and timely.

Chat Now Contact Supplier Continue in Alibaba.com App Open Cancel

Supplier Details

You May Like:

-

D1035 Auto Parts Brake Pad For Suzuki Chevrolet

Application: Chevrolet, Suzuk ...

OEM No: S451001 ...

-

Brake Pads For Volvo, Renault Truck WVA 29090

Application: RENAULT

OEM No: WVA 290 ...

-

High Quality Front Brake Pad D136

Application: DODGE

OEM No: 0446514 ...

-

58101-3XA00 OEM 581011RA00 58101-3XA00 FMSI D1543 ...

Application: Hyundai

OEM No: 58101-3 ...

-

China Brake Pads Factory Wholesale Brake Pad D699 ...

Application: Opel

OEM No: 8896409 ...

-

Premium Asbestos Free Car Brake Pad For LADA Russi ...

Application: all

-

Non-Asbestos Car Brake Pads For Toyota Corolla OEM ...

Application: all

-

Brake Pads D1533-8742 For Car Spare Parts

Application: all

-

колодки тормозные JAC T6 передние

Application: JAC

OEM No: 3501100 ...

Related Product Tags:

brake block , brake pad box , cars and bus brake pad , brake pad disc semi metal , brake pads mk , long life brake pad , toyota brake pad , brake padel , brake pads pl , brake pads production lining , brake pads sensor , benz brake pad , benz brake pads , automobile brake pad , bus brake pad , bus brake pads , c v brake pad , bmw brake padPlease send us Your Search Requirement, or you can Post a Buying Lead,

suppliers may contact you actively.